Thermal Insulation

Building envelope thermal insulation is a proven technology that contributes to energy-efficient buildings. Thermal insulation reduces unwanted heat loss or heat gain through a building envelope. This, in turn, reduces energy demand for cooling and heating of buildings and thus is a mitigation measure to reduce GHG emissions. Thus, these insulation materials have a major purpose of saving energy and protecting and providing comfort to occupants.

Download Brochure

Thermal Insulation Product Range

Panache’s thermal insulation product range -Insulmix is made of sealed expanded clay, expanded microspheres and minerals.When microspheres and clay are rapidly heated to high temperature, the water vaporizes instantaneously and the crushed expanded clay, expanded microspheres and minerals“pops” like popcorn, expanding till 20 – 40 times its original volume.All the insulating material that is used are a mix of minerals & hard grit like structures with graded particle size forming a compact structure binding ; because of this after some time due to density difference ,settling of material does not take place and air gap is not formed.

What is Thermal Insulation?

Thermal insulation is a construction material with low thermal conductivity, often less than 0.1W/mK. Thermal insulation is one kind of building insulation that is an important technology to reduce energy consumption in buildings by preventing heat gain/loss through the building envelope.

The primary contribution of building envelope thermal insulation is to provide thermal comfort to its occupants. This supports healthy living environments and better productivity in workplaces.

The building envelope includes the materials that comprise the foundation, wall assembly, roofing systems, and fenestrations (glazing, doors, and any other penetrations). The connections and compatibility between these elements are critical to ensure that the building envelope functions as intended. Insulation typically can be categorized into four families according to their material types as shown below.

1) Organic Material - Cellular - Ceramic-based products Fibrous - Glass wool, etc.

2) Inorganic Material Cellular - Cork, Polyurethane, etc. Fibrous - wood, cellulose, sheep wool, etc.

3) Metallic / Metalized Reflective Membrane Rolled Foil, Reflective Paints, etc.

4) Advanced Materials Transparent Aerogel, Phase changing materials.

The insulation value of the different insulation materials varies and is measured by its R-value (thermal resistance) or its U-value (the inverse of the R-value). Insulation materials have different ratings (R-values) and the choice depends largely on issues such as where they are going to be installed (open cavities, close cavities, the surface of the walls, attics…), price, available space, or moisture issues. A poor installation of the materials and thermal bridging can sharply reduce the effectiveness of the insulation.

In developed and industrialized countries, building codes include requirements to safeguard minimum acceptable insulation levels for building envelopes and thus provide the opportunity for deploying the application of thermal insulation technologies.

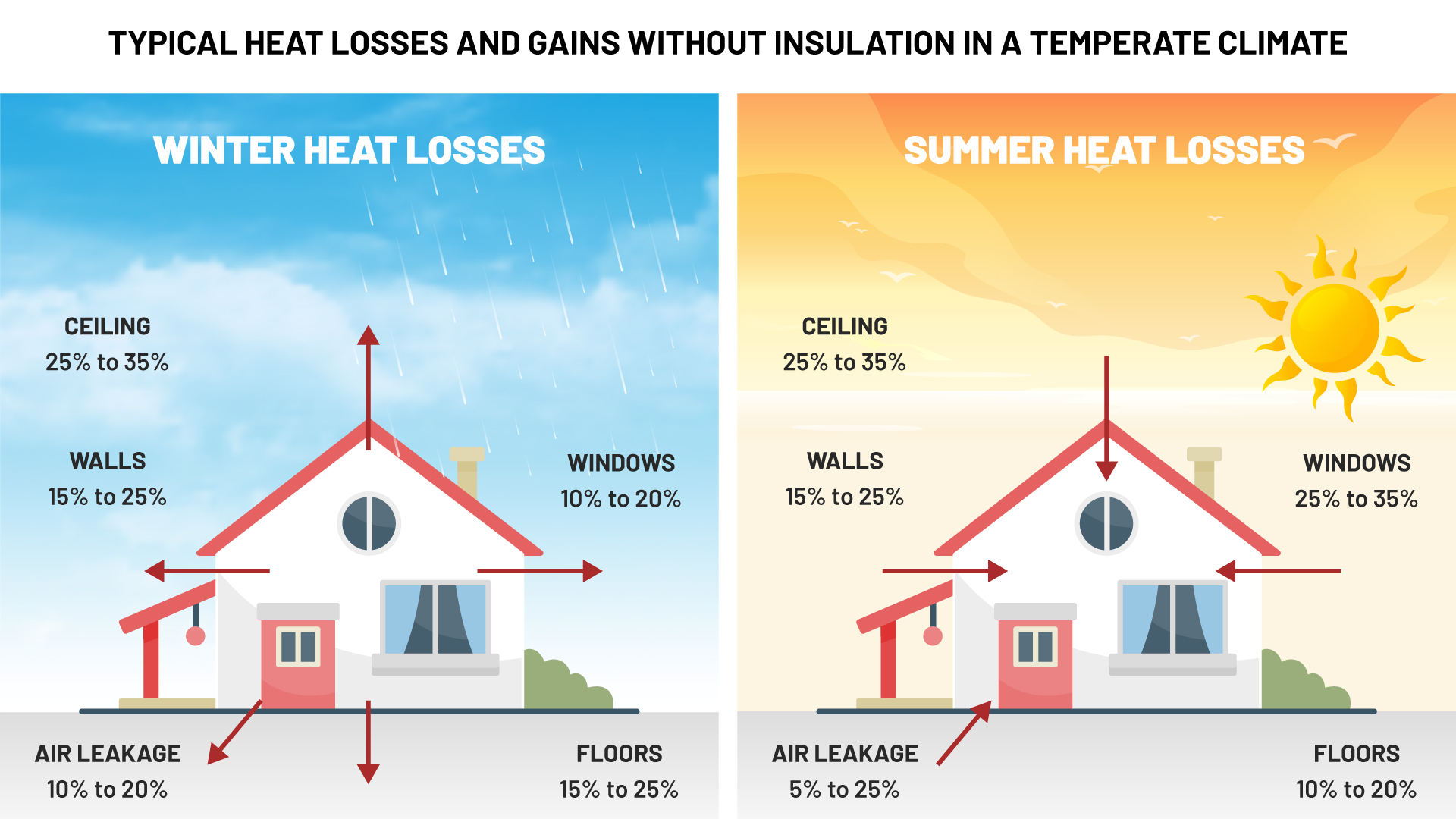

In thermal Insulation installations, good detailing and workmanship to prevent air leakage are crucial for all types of building envelope thermal insulation.

Importance Of Thermal Insulation

The fact of urbanization leads to the requirement for rapid urban development. Rapid urban development impacts us on a local, regional, and global level. A more responsible approach is required by the AEC community along with every individual. Adopting new technologies that improve efficiency and productivity is the way ahead to meet the industry races and suffice the pace & demand for new buildings and Infrastructure, considering our Planet, Climate change, and depleting natural resources are today’s pressing industry challenges.

For any construction, building envelopes play an important role. Building envelopes are defined as a physical barrier between the conditioned space and unconditioned space and/or the outside of a building. The envelope, however, does more than separate spaces.

It is a combination of materials serving several functions, including serving as a weather barrier, air barrier, sound barrier, and a natural light and wind barrier. It also improves thermal performance and can serve a structural function. Since a building envelope separates the unconditioned exterior environment from the conditioned interior space, it is one of the key factors that impact building energy consumption.

Energy-efficient building envelopes:

-

Have high thermal resistant materials in the facade of the building,

-

Use vapor barriers and are effective in vapor control,

-

Have efficient window and door seals,

-

Have effective airflow control to minimize infiltration of outdoor air.

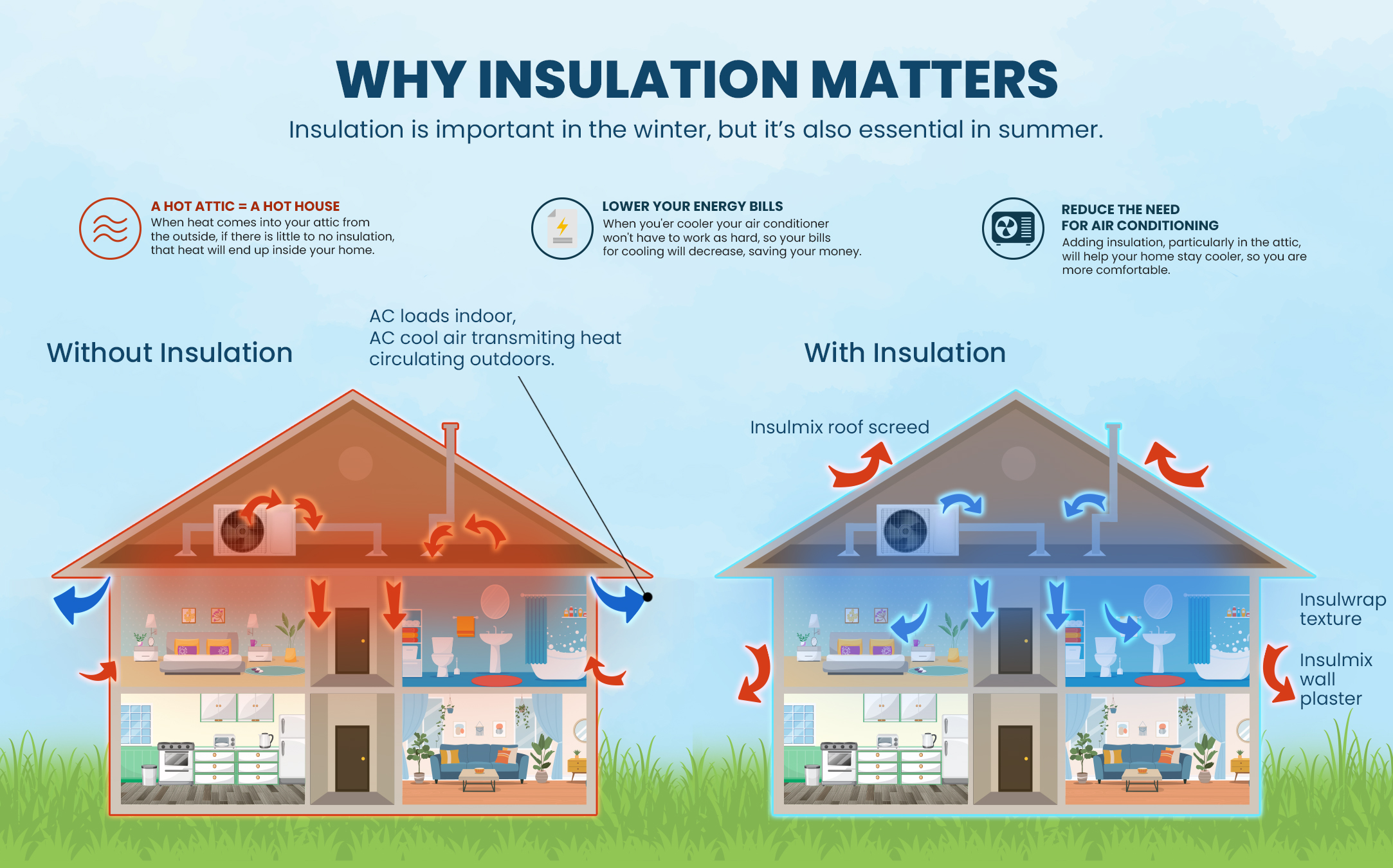

Green buildings incorporate many strategies to reduce energy use and environmental impacts and improve occupant health. Cool & Insulated Roofs are one of the most important green building strategies because of the immense positive benefits they provide. Cool & Insulated Roofs are essential to the construction and maintenance of energy-efficient buildings, providing several tangible & intangible benefits to the building owner and occupants. Cooler & Insulated Roofs mean Longer Life of construction with crack prevention & contribution to indoor cooling.

Building envelope thermal insulation is a proven technology that contributes to energy-efficient buildings. Because of the rising energy costs and the urging questions about the protection of the environment, the energy-conscious construction and thoughtful design of our buildings became a priority. Besides the ideal orientation of the buildings, and the functional layout of the premises, the designing of the continuous thermic sheath, the selection of the proper insulation material, and its thickness play an important role as well.

Our Solutions

For the design strategy for energy-efficient facades, the insulation material type and the assembly of the envelope are to be selected based on the climate type of the site location, type of construction, and availability of the materials.

We provide Four types of anti-corrosion solutions;

Climate specific design of the energy-efficient envelope can be selected based on these three climate types-

Some Facts -

In Cooling dominant countries, like India, the major heat gain is due to Solar exposure. The construction done in India is major in masonry/concrete - especially walls by cement plasters. The first and major Design strategy required in such countries is to have solar insulation or High SRI paints. The use of high SRI paints will stop the heating of walls and any structure and reduce the expansion & contraction coefficient of walls and reduce the rate of crack development.

Since the construction done in India is major in cement and concrete, the selection of material type for insulation plays an important role in the successful benefits of thermal insulation. Since in wall assembly, thermal insulation is the sandwich layer, the selection of material types having compatibility with the base structures makes the complete assembly compatible and sustainable, and workable.

Using the material of the same cement or concrete family type will reduce the difference in the heat expansion coefficient of the base substrate material, thermal insulation layer & the top facade layer. This feature will reduce the structural movement and thus the reduction in crack development. Using any other material like PU foams, Rock wools, XPS boards, thermocol, etc is prone to crack development and debonding.

Panache with its practical approach and diving deep into studying the construction modes in India has developed a Green Pro certified range of thermal insulation materials along with its application design to provide sustainable performance and life. A complete building envelope consisting of Insulation Roof Screed, Insulation Wall Plaster & Insulated Wall Texture has been developed by Panache to cater to the problems faced by the construction segment in India.

Download Brochure

Download Brochure  Enquire Here

Enquire Here